Everything You Need to Know About Double Girder EOT Cranes

People in workshops and large industrial setups often talk about lifting systems as if they are simple choices, but the moment a heavy load needs moving, the conversation changes entirely. One person mentions a beam crane, someone else recalls a double girder system from another factory, and suddenly the topic grows bigger than anyone expected. This happens because lifting requirements rarely stay the same from one place to another. We will discuss everything about double girder EOT cranes you ever wanted to know.

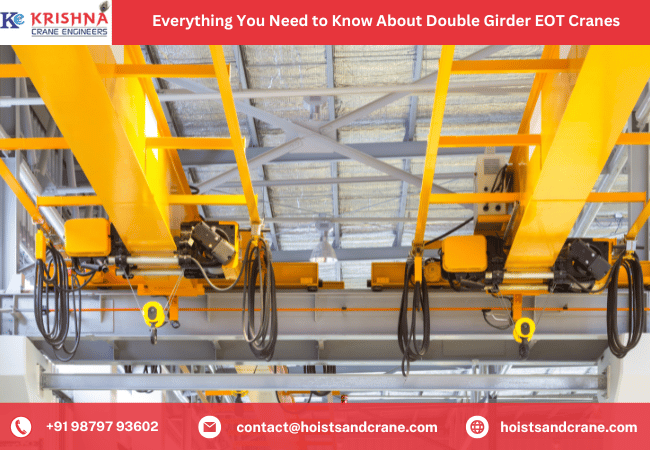

What Makes a Double Girder EOT Crane Different

The design looks straightforward from the outside, two girders running parallel, a trolley moving above them, a hoist working with a steady rhythm, yet this simple structure carries surprising strength. Anyone who has spoken to Industrial Crane Manufacturers will have heard the same explanation, two girders mean better weight distribution, and better weight distribution means safer lifting.

Some companies, including well known Double Girder EOT Crane Manufacturer in India groups, build these cranes with long daily shifts in mind. The cranes are not only about capacity, they are about durability under repetitive tasks.

Applications of These Cranes

Factories that handle heavy molds, steel components, large machinery, and casting units rely on these cranes because they do not like surprises. Heavy Duty EOT Cranes need a frame that behaves predictably even when the load is not perfectly balanced. Two girders offer that comfort.

There are also places that choose double girder models simply because they want better hook height. A single girder crane loses some lifting space, but a double girder sits higher and lets the hook reach closer to the ceiling. This becomes important when tall materials pass through the same track repeatedly.

And some companies, especially Top Crane Manufacturers in India, point out that the extra space between girders helps fit larger trolleys, more advanced controls, and better safety systems.

The Crane in Motion, Where the Real Story Happens

The crane may look impressive when still, but its personality shows only when it starts moving across the workshop. Movement is where everything comes together, the rail alignment, the wheel balance, the hoist performance, and the operator’s control. Overhead Crane Manufacturers in India often test their cranes in long trial runs because even a slight vibration tells a story about how the crane will behave once installed.

In real working spaces, loads do not always sit perfectly centered. Some sway, some twist, some resist turning. Reliable Lifting Solutions depend on the crane absorbing those small imperfections. Workshops with uneven workflow patterns benefit the most from double girder designs because the crane stays calm when the load does not.

How Different Parts Form a Single Working Unit

There are rails stretching across the building, steel columns carrying the load, the crab trolley running between the girders, and the hoist lifting and lowering with slow controlled movement. Each part plays a role. A weak girder affects stability, a misaligned track affects braking, and a worn out wheel affects the entire movement.

Companies like Reva Cranes Engineers and other Award winning Crane Manufacturer groups always highlight that a double girder EOT crane is not one machine, it is a collection of systems that must agree with each other. If one piece fails, the strain shifts to another, then another.

Choosing the Right Model for the Right Space

A double girder crane looks powerful in photos, but choosing the right one requires more questions than many expect. EOT Crane Manufacturers in India often visit the site before recommending a model. A small change in column spacing or floor layout can turn the decision upside down. Sometimes the crane that looked perfect on paper does not turn properly in the actual space. Sometimes the heavier model is unnecessary, and a lighter configuration works more efficiently.

Maintenance, Checks, and Long Term Rhythm

Once installed, a double girder crane becomes part of the daily sound of the workshop. It moves quietly above everything, working almost like a dependable routine. But it needs care. Motors, couplings, rails, brakes, and limit switches all need small checks that prevent bigger problems later. Industrial units that maintain logs and follow regular inspections end up with cranes that last decades. Others that ignore simple checks eventually face delays, shutdowns, or expensive repairs.

Conclusion

Double girder EOT cranes bring strength, balance, and day to day reliability into spaces that cannot afford hesitation during lifting. They stand above the workflow, yet their presence shapes everything below. When companies explore options and need someone who understands both the structure and the daily load pattern, a trusted double girder EOT crane manufacturer becomes the most dependable guide, helping businesses choose a crane that fits naturally into the life of the workshop.