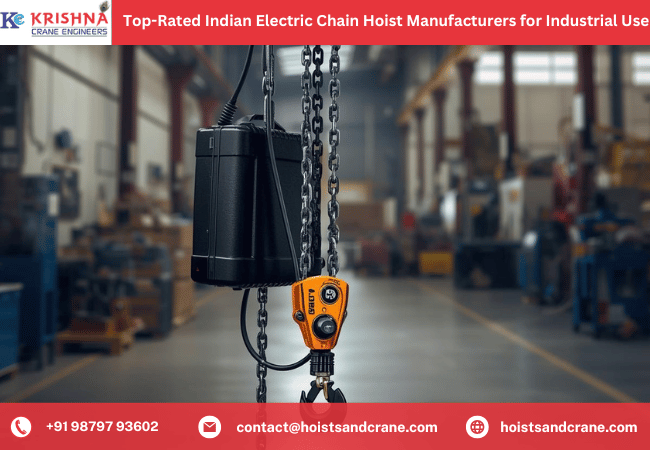

Top-Rated Indian Electric Chain Hoist Manufacturers for Industrial Use

People inside busy workshops or large factories usually notice machines first, the heat from them, the noise, the way everything seems to move in its own pattern, and somewhere above all of that, there is always lifting equipment quietly carrying the load. Someone mentions a lifting spreader beam, someone else brings up hoists, and suddenly the conversation shifts into a world of lifting tools that keep everything running smoothly. Electric chain hoists, especially, end up becoming part of the daily rhythm without anyone really thinking about it. They help teams lift goods again and again, and they do it without slowing the pace of work.

Why Electric Chain Hoists Matter in Industrial Work

Electric hoists have a strange way of looking simple until someone watches them work. A motor, a chain, a hook, some controls, but in practice, the way they carry a load changes everything happening around them. Factories do not have time for slow lifting or uncertain movements, so electric hoist manufacturers in India spend a lot of time designing hoists that behave predictably.

Some places use them for small parts, others for heavy equipment. Some hoists do short lifts all day long. Others work in tall bays where the chain needs to travel far. And this difference in usage makes customisation common, almost necessary.

The Manufacturers Who Shape the Market

There are many chain hoist suppliers in India that appear again and again in conversations. A few belong to electric hoist manufacturers in Gujarat who built their reputation through consistent performance. Some companies are known more for their electric chain hoist company services, especially when clients need installation and long term support. Others earn trust through durable parts, spare availability, and well balanced motors that do not overheat during long shifts.

What Buyers Pay Attention To

Workers and supervisors may not speak in technical terms all the time, but they notice how the hoist behaves. They notice if the braking system feels smooth or too sharp. They notice if the chain jumps slightly. They notice if the hook twists at the wrong time. These small behaviours decide whether a hoist feels good to use or becomes something workers quietly avoid.

Industrial lifting equipment becomes valuable when it blends into the background. When it becomes part of the routine. And this happens only when the manufacturer understands how hoists behave in the real world, not only in brochures or test rooms.

Fitting Hoists Into Different Work Environments

Hoists work with cranes, beams, rails, and building structures. A hoist that fits one workspace perfectly may not fit the next. Material handling equipment India includes all kinds of tools that connect to the hoist’s purpose, and manufacturers must consider everything around the hoist, not just the hoist.

Some plants have high roofs and want long lifting travel. Some have low roofs and want compact hoists. Some have machines placed very close together. Others have wide open bays. This is why chain hoist manufacturers spend time studying onsite conditions before suggesting a model.

Manufacturers With Strong Footprints Across India

Some electric hoist manufacturers in Gujarat work closely with heavy industries, so their hoists usually look stronger and carry bigger safety margins. Others focus on lighter, fast moving assembly setups where precision matters more than brute strength. Hoist and crane manufacturers who offer complete solutions often have an advantage because they understand how the hoist interacts with cranes. They make better choices about motor sizes, brakes, hook design, and chain length.

Maintenance, Longevity, and What Happens After Installation

Once the hoist arrives, it becomes a tool used daily, often without a second thought. But every electric chain hoist for industrial use needs attention eventually. The chain stretches, the motor warms up after long cycles, limit switches need testing, bearings need lubrication. A good hoist lasts years, sometimes decades, when these small checks happen at the right time.

Manufacturers who support maintenance earn trust. Some offer quick spares, some send teams for inspections, others provide guidance for in-house technicians. And that support ends up shaping long term satisfaction more than the initial purchase.

Conclusion

Across different factories and workshops, hoists slowly become part of the daily rhythm, almost like a tool people forget to notice because it works the way it should. And choosing one is less about the largest capacity and more about how well the system settles into the space, how comfortably it moves, and how easily the workers adjust to it. Some environments want a simple setup, others lean heavily on industrial lifting equipment, and a few want hoists that match the pace of their busiest shifts. That is why companies often end up depending on experienced chain hoist manufacturers, who help lift goods safely and consistently.