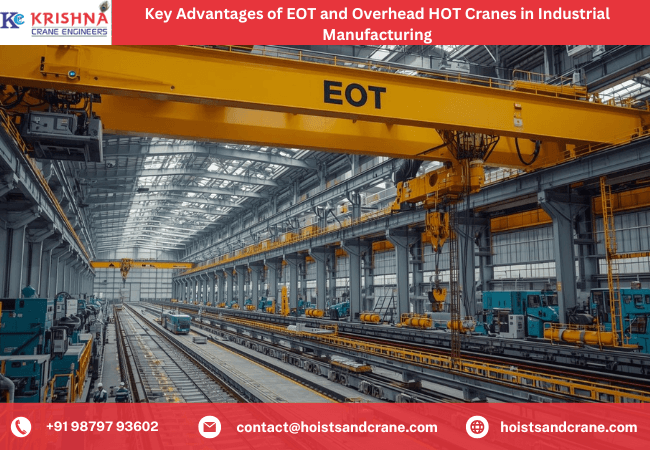

Key Advantages of EOT and Overhead HOT Cranes in Industrial Manufacturing

In today’s world, efficiency, precision, and safety form the basis of smooth manufacturing operations. Cranes are one of the most important machines used in the industrial setting as they play an essential role in running industries and factories. They help move heavy loads, save time, and reduce the physical strain on workers. To be specific, Electric Overhead Traveling (EOT) cranes and Overhead Hand Operated Travelling (HOT)Cranes play a vital role in industrial settings and we will discuss key advantages of them in this article.

Understanding EOT and Overhead HOT Cranes

An EOT crane is an electrically operated system that runs on rails fitted at a certain height along the factory’s structure. It moves materials both horizontally and vertically with the help of a hoist. EOT cranes can be operated manually or through remote control, depending on the model and requirement.

HOT (Hand Operated Traveling) cranes, on the other hand, operate in a similar way but are typically driven by manual control mechanisms. Though not as advanced as EOT cranes, HOT cranes remain an affordable and efficient choice for industries that handle moderate loads or require simple lifting systems.

Advantages of EOT and Overhead HOT Cranes

- Enhanced efficiency and productivity

One of the greatest advantages of EOT and HOT cranes is their ability to streamline material movement. They allow factories to handle large volumes of raw materials or finished goods quickly and with minimal manual effort. This automation reduces downtime and improves workflow across the production line. Instead of using forklifts or relying on human strength, a single operator can control the crane and complete the job in minutes.

- Safety and risk reduction

Safety is a top concern in any manufacturing environment, especially where heavy materials are involved. EOT and HOT cranes significantly reduce the chances of accidents caused by manual lifting. They are designed with advanced control systems, limit switches, and safety brakes that ensure stable operation even under heavy loads. These cranes also keep workers away from potentially dangerous lifting areas, lowering the risk of injuries..

- Precision and control

Industrial manufacturing often requires precision when moving materials. EOT cranes are equipped with accurate positioning controls that allow operators to lift and place loads exactly where they are needed. This accuracy is especially valuable in industries like automobile manufacturing, steel fabrication, and assembly lines, where even a small misalignment can cause production delays or defects. The smooth operation and fine control offered by these cranes result in minimal product damage and reduced waste.

- Space Optimization

In most factories, space is limited and must be used wisely. EOT and HOT cranes are installed overhead, which means they don’t occupy valuable floor space. Unlike mobile cranes or forklifts that move around on the ground, overhead systems leave the working area free for other operations. This setup allows industries to make the most of their existing infrastructure without requiring large expansions.

- Cost-Effectiveness

While investing in an EOT or HOT crane may seem like a big expense initially, it proves to be cost-effective in the long run. The reduction in manual labor, quicker material movement, and fewer accidents all lead to significant savings. These cranes are built for long-term use with minimal maintenance when serviced regularly. Moreover, the ability to handle heavier loads efficiently reduces wear and tear on other equipment. This helps extend the life of both the cranes and the overall machinery used in the production process.

- Versatility in application

EOT and HOT cranes are designed to serve a wide range of industries. Whether it’s metal processing, construction material handling, power generation, or logistics, these cranes adapt easily to various load requirements. They can be customized to different capacities, spans, and speeds, making them suitable for both small-scale industries and large-scale manufacturing plants. This flexibility is one of the main reasons industries continue to rely on them heavily.

- Reduced downtime and easy maintenance

Modern cranes come with user-friendly controls and diagnostic systems that make maintenance simpler. Routine checks can be carried out quickly, minimizing operational downtime. Spare parts are easily available, and many EOT and HOT cranes are designed for easy access to components, ensuring that any repairs or replacements can be done without major disruptions.

Conclusion

EOT and overhead HOT cranes are not just lifting machines but are essential partners in improving manufacturing performance. Their contribution to safety, speed, and accuracy makes them a valuable asset for any industrial setup. By investing in the right equipment, companies can achieve long-term efficiency and a safer working environment.

For industries looking to enhance their material-handling systems, partnering with reliable Overhead cranes manufacturers ensures that the cranes are designed to meet specific operational needs, offering durability, efficiency, and unmatched performance.